Precision Machine Work, Prototype Development

Scientific Instrumentation

Mithra Technologies is one of the few machining facilities that specializes in the development of scientific equipment, specifically catalyst evaluation instrumentation and multiphase reactor systems. Our staff combines Ph.D. engineering scientists with skilled machinists to develop novel instrumentation to address the experimental challenges of the laboratory.

Prototype development can begin with only an idea. Our services include design and CAD drawing, fabrication, assembly and testing. We can integrate data acquisition and control, automation and electronics development. We focus on thoughtfully designed and well made prototypes rather than high volume production.

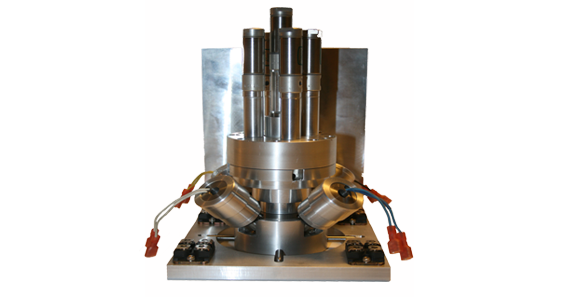

Our distinction is in streamlining the process between scientist, designer and fabricator saving time and money in the development process. Since 1990, we have be the driving force behind the TAP (Temporal Analysis of Products) Reactor System used in catalyst development. We design and manufacture custom build UHV systems and flanges for mass spectrometry, surface science and high energy physics experiments. Our current focus is the development of novel multiphase reaction instrumentation and reactor systems needed for new catalyst design.

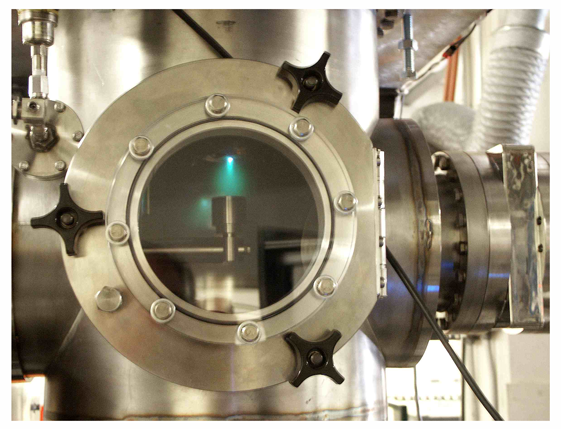

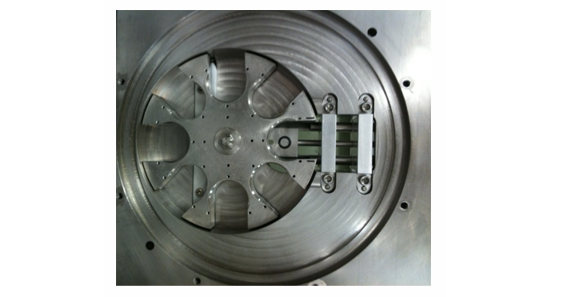

Custom Vacuum Systems

We have experience in the design and construction of large vacuum vessels that can attain ultimate pressures of 10^-9 torr. We use a double O-ring system where the differential space is pumped with helium to effectively replace the natural outgassing of nitrogen and oxygen with helium. Our techniques minimize oxide formation, porosity and virtual leaks that are difficult to diagnose and eliminate. We also custom design large gate valves and actuated baffles that are integrated directly into the chamber design.

We have experience in the design and construction of large vacuum vessels that can attain ultimate pressures of 10^-9 torr. We use a double O-ring system where the differential space is pumped with helium to effectively replace the natural outgassing of nitrogen and oxygen with helium. Our techniques minimize oxide formation, porosity and virtual leaks that are difficult to diagnose and eliminate. We also custom design large gate valves and actuated baffles that are integrated directly into the chamber design.

.

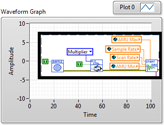

Software Automation and Data Acquisition

We provide custom software for control system automation and data acquisition from theLabview (TM) and Visual Basic (TM) platforms. This includes field wiring of sensors, servos and actuators, and plumbing of

We provide custom software for control system automation and data acquisition from theLabview (TM) and Visual Basic (TM) platforms. This includes field wiring of sensors, servos and actuators, and plumbing of  pneumatics to deliver turnkey control panels ready for field installation. All our instruments are designed for fail-safe operation over an internet protocol so that end users may conduct experiments from anywhere in the world no matter where the device is installed.

pneumatics to deliver turnkey control panels ready for field installation. All our instruments are designed for fail-safe operation over an internet protocol so that end users may conduct experiments from anywhere in the world no matter where the device is installed.

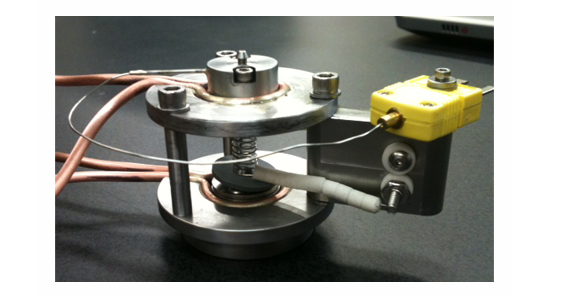

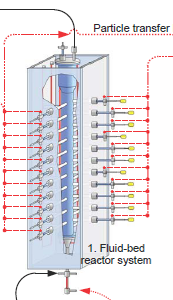

Multiphase Reactions and Reactor Systems

A key focus of our present initiative is to develop innovative tools to study macroscale multiphase reaction systems with nanoscale surface modification and kinetic characterization techniques. Our methodology is to embrace the complexity of technical catalytic materials and their operating environment in a top-down approach; capturing materials from the working environment then testing using probe molecules in a manner that does not change the 'kinetic state' of the material.

A key focus of our present initiative is to develop innovative tools to study macroscale multiphase reaction systems with nanoscale surface modification and kinetic characterization techniques. Our methodology is to embrace the complexity of technical catalytic materials and their operating environment in a top-down approach; capturing materials from the working environment then testing using probe molecules in a manner that does not change the 'kinetic state' of the material.